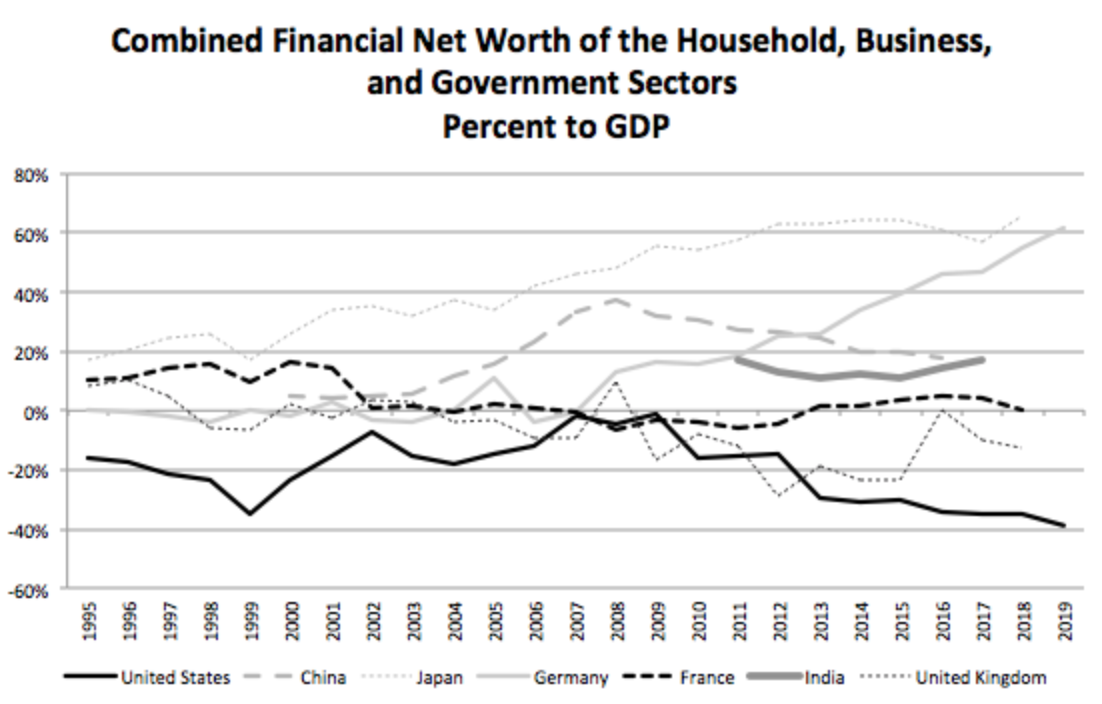

The United States currently has a problematic trade deficit, not only with China but globally. U.S. imports exceeded its exports by $80.4 billion in October of this year alone. This trade deficit increases the debt burden of U.S. households and businesses; depletes our country’s financial capital (See Chart 1); contributes to rising inequality; and makes wage growth all the more difficult.

Chart 1

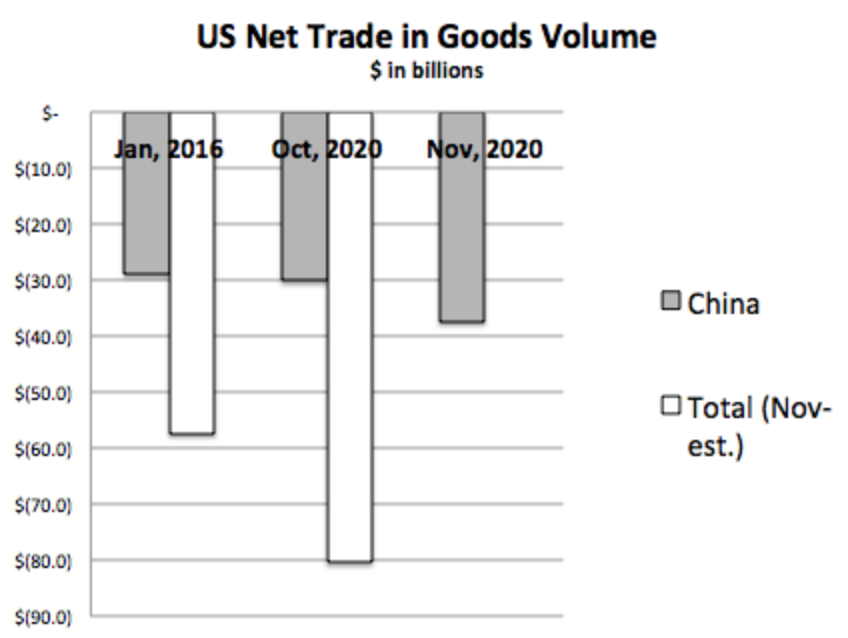

At least in his concern about the trade deficit with China, Donald Trump was on to something. Yet his confrontational and clumsy approach to this problem resulted in nothing but lost ground. Our trade deficit with China did not improve during his presidency, and our trade deficit with the world grew significantly worse (See Chart 2).

Chart 2

Trump failed on trade because he relied exclusively on tariffs, which are a fickle tool in a world where currencies float, trade retaliation by other countries comes quickly, and supply chains are complex. While tariffs have their place, and have been part of U.S. trade history, they are only one small part of a bigger equation.

So if Trump’s tariffs didn’t work, how can we improve our balance of trade?

The answer is obvious but so widely overlooked that it might sound like heresy: To improve our balance of trade, we should make better and more advanced products and services. That has been our advantage for 150 years—so much so that our product and service superiority is almost taken as a given. Don’t we export the best products and services in the world?

A country’s exports can be measured by their complexity, which is a way to gauge this aspect of trade. In today’s world, complex products include such items as high-end medical and surgical devices, robots, specialized industrial equipment, high-end computers and telecommunications equipment, and genetically engineered biological materials. The Observatory of Economic Complexity, originally founded by MIT, publishes an index called the Export Complexity Index (ECI) which does this very thing. Not surprisingly, the perennial export powerhouses—Japan, South Korea, and Germany—rate among the highest on the ECI index with recent ratings of 2.39, 1.97, and 1.95 respectively, and, for each, these indexes are rising. Their respective average export surpluses over the last 20 years as a percent of GDP have been 0.5 percent, 3.2 percent, and 5.4 percent.

The United States ranks 13th among the world’s countries, with an index of 1.44, a decline from an index of 1.54 in 2011. China is 20th at 1.18, but its index has been rising crisply from the 1.01 it registered in 2011. The U.S. average net export surplus has been negative 3.8 percent over the last 20 years, while China’s is a positive 3.4 percent. China is now the country with increasingly more complex exports as compared to the United States.

One group of researchers affiliated with University of California at Berkeley, MIT, and other major universities took this analysis a step further. They adjusted the ECI to account for the difficulty of exporting each product and the volume of a given country’s exports in order to create an index they call the ECI+. This index takes into account that the harder it is to export a product—for example, a large aircraft—the greater the competitive advantage of existing exporters, due to the difficulties faced by new entrants hoping to compete. By this index, China is first in the world and rising and the United States is fourth and trending downward.

This trend matters immensely, since globally the most complex and advanced products are most likely to command price premiums and attract very high demand. And this complexity is now found across an ever-broader range of products since today even cars and household appliances are computers. In health care, an increasingly dominant economic category, products offered for export are becoming exponentially more complex, and include manufactured biological and genetically reengineered materials.

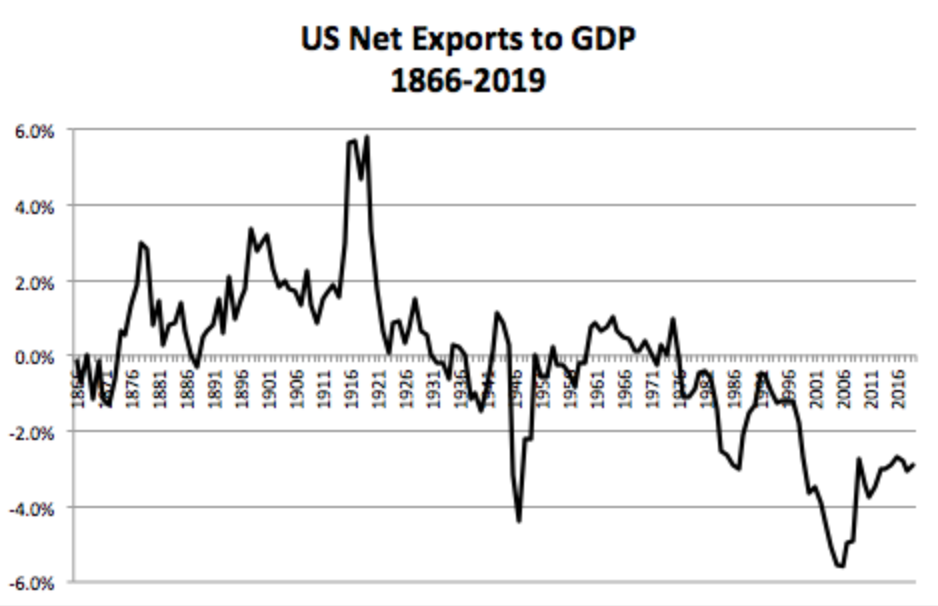

Chart 3 shows the U.S. net export position from after the Civil War to the present. It was good, even robust, until roughly 1981, and has been largely negative since then. Keep in mind that this is both goods and services, so the rationale that our trade position has changed because we have shifted to services doesn’t hold up because the services we export are included in the calculation.

At a very fundamental level, trade is a measure of the relative net demand for our products and services, and therefore a measure of the desirability and appeal of those products and services. This more fundamental aspect of the issue seems to have been lost in the obsession with tariffs. The higher the appeal and demand for a given product or service, the more power the company offering it has to command high prices, a factor sometimes referred to as “pricing power.”

One more thing: The more pricing power a company has, the greater its capacity to pay higher wages. The more advanced a product is, the greater the skill required to make that product, and higher wages follow higher skill levels. Thus, if we are seeking higher U.S. wages, then more advanced products and services can be a meaningful part (although far from the only part) of the solution.

Here’s the catch. The most advanced products and services come largely from intensive, long-term, foundational, and basic research, the kind that most companies cannot afford to undertake because the payback is so often measured not in months or years but in decades. This would include research in artificial intelligence, 5G and 6G communications networks, biotech and genetic engineering, electric vehicles and batteries, supercomputing, quantum encryption, and high-tech manufacturing. The research needed in these areas is far deeper and more expansive than what private-sector companies currently undertake. It most often comes from government support of academic research in the most advanced laboratories and with the most extraordinarily cutting-edge research and engineering.

But U.S. government funding for research and development (R&D) has been declining as a percent of our national income for more than 50 years. From 1964 to 2018, total federal funding of R&D has dropped by nearly two-thirds relative to GDP, from 1.83 percent to 0.66 percent. Trump showed no interest in reversing this U.S. decline. Meanwhile, in the past ten years, China’s central government funding for science and technology has tripled in real yuan.

It’s stunning. Since 2000, the U.S.’s “R&D intensity”—its expenditure on R&D not only by the government but also by academia and industry as a percentage of GDP—has been fairly flat, and currently stands at 2.8 percent. That’s slightly above the world average, but well below Israel’s 4.9 and South Korea’s 4.5 percent. In that same period, China’s R&D intensity has more than doubled, from 0.9 percent to 2.1 percent. So we still lead China here, but China has passed the EU in R&D spending, and its brisk growth in this area is projected to continue, while ours is at risk of remaining static.

The gradual abdication of our global research leadership has occurred at the very time that China has been deliberately pouring funds into the most advanced technologies. China has made clear its national goal of becoming the dominant global, high-tech manufacturer by 2025, an international leader in innovation by 2030, and a world powerhouse of scientific and technological innovation by 2050.

This research and innovation gap is much more the story of our trade deficit than the lack of high tariffs.

Yet the raw facts of this story are unknown to most, and of little concern to others who do know them. In fact, some believe that it is not the place of government to provide research and development funding. Some insist the marketplace should be the sole source of business funding, including R&D funding, and that the government should not subsidize industries, products, companies, or markets; in other words, the government should not be in the business of “picking winners.”

But that belief reveals a troubling ignorance of American business history. The U.S. government has been actively supporting business advancement from its earliest days, starting with its support and guidance of the colonies’ meagre manufacturing capabilities to help them build weapons for the American Revolution. This was quickly followed by Alexander Hamilton’s 1791 Report on the Subject of Manufactures and the establishment of the accompanying state-sponsored, tax-advantaged Society for the Establishment of Useful Manufactures, in Paterson, N.J. The Report on Manufactures was an overt call by Hamilton for the United States to fully join the Industrial Revolution, certainly the most profound business revolution in world history.

The most consequential U.S. economic development of the early 1800s was the state-funded Erie Canal. That was followed by decades of government support and subsidies for railroads, the most important industry of the nineteenth century, including land grants and other support for the Illinois Central Railroad and the Transcontinental Railroad. This support often came after purely private efforts had failed.

In 1832, Abraham Lincoln first entered politics by championing government support for internal improvements that were almost entirely intended to improve trade and commerce. After he became established as a lawyer, Lincoln’s best-paying client was the Illinois Central.

Another crucial nineteenth-century development was the telegraph, and Samuel F.B. Morse’s test telegraph line between Washington and Baltimore was funded by a $30,000 grant from Congress. He gave a high-profile initial demonstration of this new technology in 1844.

In the 1870s, Congress allocated funds to form the National Board of Health, with the initial goal of investigating the causes of epidemic diseases such as cholera and yellow fever. That led to today’s National Institutes of Health (NIH), whose support by the government has been responsible for a vast number of recent pharmaceutical breakthroughs.

In 1940, Vannevar Bush, founder of Raytheon and former dean of MIT’s School of Engineering, proposed an idea to President Roosevelt for a new federal agency to help coordinate scientific research with military relevance. That proved so successful in the war effort that it inspired the creation of the National Science Foundation (NSF) in 1950, which has been an ongoing boon to business innovation ever since.

The Manhattan Project to develop an atomic bomb during World War II led to hundreds of innovations subsequently commercialized by U.S. businesses. The massive expenditures in the space and arms races with the Soviet Union financed and boosted innovation on the microchip and many other technologies. The government’s support of microchips for missiles and space exploration alone reduced the price of a single chip from $32 in 1961 to $1.25 just ten years later, making computers affordable for the masses.

The Soviet Union’s successful launch of the satellite Sputnik in 1957 spurred the passage of the Small Business Investment Act in 1958. The small business investment companies (SBICs) created by that Act provided the funding that constituted three-quarters of venture capital between 1959 and 1963 and jump-started the modern venture capital industry. SBIC funds helped meet the early capital needs of companies such as FedEx, Tesla, Apple, and Intel.

The iPhone, perhaps the most iconic, consequential artifact in the world today, was built on technologies that emerged directly out of, or were significantly enhanced by, many large-scale government research efforts. This list includes the invention of the Internet itself; microprocessors and central processing units; dynamic random-access memory; micro hard drive storage or hard drive disks; liquid-crystal displays; lithium-polymer and lithium-ion batteries; digital signal processing; the Hypertext Transfer Protocol and Hypertext Markup Language; cellular technology and networks; click-wheel navigation and multi-touch screens; and artificial intelligence, with voice-user interface.

These examples are just one small part of the story, and they underscore that for many of the most important economic developments in our nation’s history, it wasn’t the marketplace that determined success, but the government in concert with the marketplace. Huge swaths of American business success have been built on government-funded R&D. This investment has been central to the United States’s rise to global preeminence.

This history and the current R&D gap between the United States and other developed countries speak to our ongoing need for an overt industrial policy that focuses government-funded research on areas that will bring robust growth. The amounts required to restore a more robust effort here are not overwhelming in relation to the government’s overall budget of $4.5 trillion. A 10 percent increase in our federal R&D spending would total a mere 0.35 percent of that budget. A doubling would total 3 percent of that budget and would supercharge and completely revolutionize our economy within a generation, bringing a flood of higher-paying jobs.

Yet even with this renewed investment and industrial policy, we will not capture the full benefit of our innovations unless we also commit to the research and development necessary to manufacture these new and advanced products in the United States. If we develop a spectacular new product but don’t manufacture some or most of its components in the United States after it is commercialized, then we will have won only half the battle.

Our manufacturing prowess, good as it still is, has slipped in relation to advanced manufacturing in other parts of the world.

Years ago, when products were simpler, all the crucial intellectual property and intellectual capital resided in product development and design, and assembly and manufacturing could be sent offshore to lower-wage countries without ceding any of that intellectual capital. Manufacturing was straightforward and could easily be re-shored if needed, or so we thought. With that, business leaders and policymakers concluded that there was little intellectual capital to be lost by offshoring manufacturing.

Today, the complexity of products means that there is almost as much intellectual capital and intellectual property in the manufacturing process itself as in product development. Thus, for an increasing number of products developed in the United States but manufactured elsewhere, even without consideration of wage differences, there is simply not the option to re-shore because the intellectual capital and manufacturing skills needed to manufacture it here have atrophied or been lost. For increasingly complex products such as high-end computing and telecommunications equipment, manufacturing is a form of intellectual capital unto itself.

But there is hope. Advancements in manufacturing automation, both actual and possible, now mean that the labor component of product cost is declining and thus the significance of labor cost differences are disappearing. With that, re-shoring has become increasingly feasible.

These are jobs that have long since been lost to other countries because this manufacturing has been moved wholesale and in its entirety to these other countries. Greater automation of the process means that this manufacturing can be moved back to the United States. The people hired to work in these now re-shored plants will be net new jobs for the United States. And they will be higher skilled, higher paying jobs—both the front-line jobs and, more importantly, the engineering, design, and administrative jobs to run these re-shored plants. Overall, U.S. job growth will accelerate.

Yet, since so much U.S. manufacturing knowledge has been lost, much of that prowess will have to be developed anew, which will take years and involve significant new manufacturing design, tooling, and training costs to create the more highly automated manufacturing design to make reshoring economically feasible—costs that many companies simply can’t afford.

For example, a small electronics firm that I know has all its manufacturing done in China because it is two-thirds less expensive to do it there than in the United States. That’s assuming a U.S. manufacturer could even be found with the technical ability to handle the job. However, this firm has now applied for a Small Business Innovation Research (SBIR) grant sponsored by the NSF for the purpose of creating a more automated and streamlined manufacturing process that could make re-shoring possible. If it receives that grant, it can afford the engineering changes that would both streamline the design—e.g., the use of fewer and less expensive materials, and simpler or fewer parts—and greater automation in product assembly. This company couldn’t afford to engineer these design changes otherwise. But with those changes, it will become feasible to manufacture that product in the United States at a cost much more comparable to its offshore manufacturing cost.

Yet SBIR budgets aren’t nearly large enough to accomplish the re-shoring revolution we could hope for. An added investment as small as 1/10th of 1 percent of the budget could bring a profound change here and provide a very happy ending to the story.

At the very least, more automated manufacturing processes would make this type of manufacturing more “portable”—more easily moved from China to another country; if not the United States, then Vietnam, Singapore, or elsewhere.

Here’s another example—a breathtaking example of truly twenty-first-century manufacturing. At the University of Pennsylvania, scientist Carl June and his team of researchers, whose work I have supported, have pioneered what is effectively a cure for certain types of cancer, including acute lymphoblastic leukemia.

The procedure for this treatment involves taking out a select number of a patient’s T cells and then genetically reengineering and reprogramming the DNA in those cells to attack and destroy the cancer tumors. In most cases, once these modified cells are reintroduced into the patient’s body, that patient is cancer free in a matter of days—an almost miraculous result.

The process for genetically reengineering those cells is quite simply a manufacturing process, complete with an assembly line, albeit one that operates near a temperature of absolute zero. Manufacturing facilities staffed with well-paid technicians and scientists have been built in Pennsylvania for this purpose. If Pennsylvania continues to invest in this type of genetic engineering research, it can reclaim the preeminent role in manufacturing that it held over a century ago, led by the most cutting-edge manufacturing in the world.

We want and need this type of manufacturing to remain on our shores. It too will result in many new, high-wage U.S. jobs.

Increasing government funding of basic research could supercharge America’s product development and advancement. With that, we could regain and solidify our leadership in the most impactful new areas of opportunity—the areas mentioned above that include artificial intelligence, 5G and 6G communications networks, biotech and genetic engineering, electric vehicles and batteries, supercomputing, quantum encryption, and high-tech manufacturing. With better, more advanced products would come an improved balance of trade, more capital accumulation, and even a much-needed platform for higher wages.

A brief technical aside: Many of my economist friends tell me that since the dollar is the world’s reserve currency, and thus other countries are compelled to hold dollars, some level of current account deficit, of which the trade deficit is the biggest part, is inevitable. I’m not entirely convinced this is true, especially since the United States had a current account surplus for much of the 1960s and ’70s, a period in which we were already the world’s reserve currency. But even if I concede the point, it is still a matter of degrees. I frankly wouldn’t mind a current account deficit of less than 1 percent, as compared to the 2 to 3 percent where it currently stands.

So let’s help tackle the trade problem the right way—the powerful way—by increasing America’s investment in core and basic research and development.

This essay was originally published in Democracy: A Journal of Ideas